WHAT IS DIGITAL PRINTING?

Digital printing uses a toner like used in laser printers or other large printers that uses liquid ink for printing.

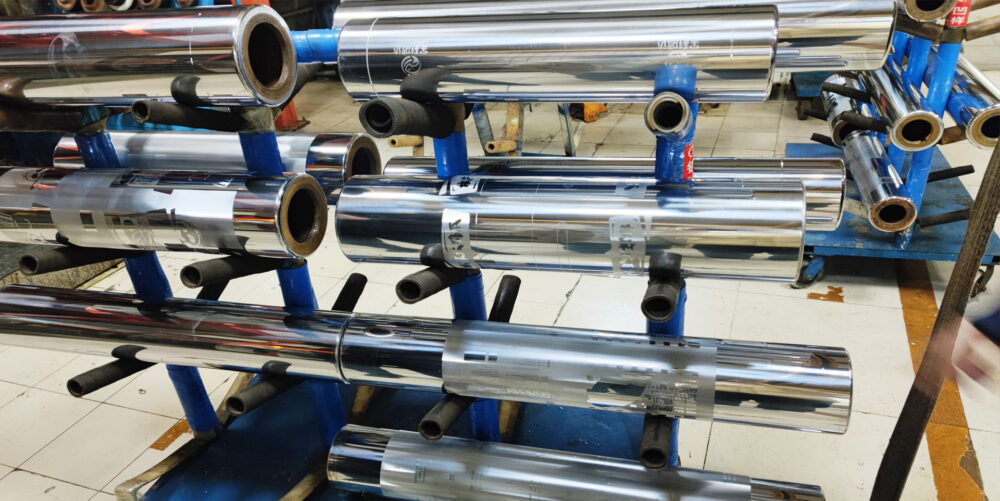

WHAT IS GRAVURE PRINTING?

Gravure is a relief print process that uses an engraved, often metal, print plate to transfer a design by rolling through ink and onto the printing surface.

The Gravure printing method is named after the printing plate, that is, all printed patterns and characters are engraved on the printing plate. When printing, first scrape off the excess ink on the printing plate (the ink on the non-printing surface), and then apply appropriate pressure to the printed matter between the printing plates through the embossing rubber roller to squeeze the ink from the concave surface to the surface. A printing method that achieves the purpose of printing on the printed matter.

The advantages of gravure printing and digital printing:

DIGITAL PRINTING

- There are no Printing Plates Costsor Cylinder fee

- Fast delivery time: generally 5-7days, urgent orders can be completed within 3days.

- Lower minimum quantities (as low as 200~500 pieces per print, depending on how many SKUs you have)

- Variable data capability (names, addresses, codes, or numbering can be done easily)

- More expensiveunit price: Generally more than2-3 times the unit price of gravure printing;

Advantages: The cost is much lower for a small number of color printing bags, because there is no plate-making fee, and the delivery time is short, suitable for testing the market and new product development.

GRAVURE PRINTING

- The production time is long, and it usually takes 15-20 working days according to different customized requirements.

- Lower unit price, Only 1/4 or even lower of digital printing.

- A larger variety of material structure types with custom finishes can be used

- Special custom inks such as metallic, Frosted ink, Mix matte and glossy printing, and Pantone colors are available

- Highest possible printing quality, with greater detail and color fidelity

Advantages: Low unit price. The Cylinder Cost is only a one-time investment. You only pay the cylinder fee for the first order and no more for repeat orders. Generally specking,the Cylinder fee will be no longer charged within the validity period of the plate roll (24 months). If it needs to be charged after 24 months, you can just update the design, which is for long-term stability. Stable orders with big quantity are suitable for gravure printing technology.