People have been using lots of plastic bags every day. I think many people are curious about how plastic packaging bags are produced. Let me introduce the printing steps and production process of plastic packaging bags to you.

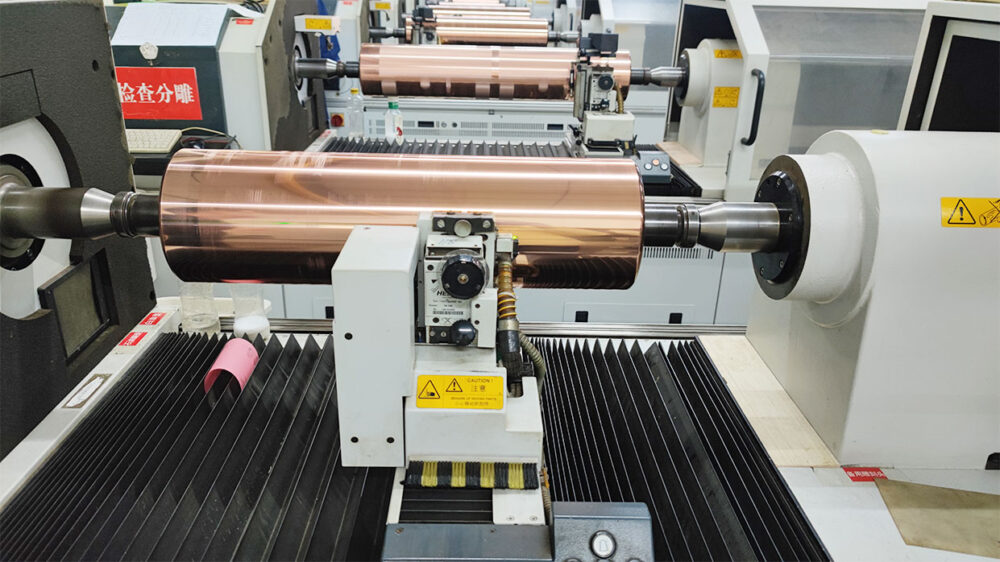

Plate making(We also call it Cylinder making

Plate-making refers to the production of original plates (for printing) according to the requirements of customers. Commonly used original plates include electric engraving plates, copper plates, offset plates, and screen plates. The most commonly used ones are copper plates

The service life of a plate(cylinder) is to print 200,000 meters of roll film. As the printing volume increases, the plate will wear out, gradually the printing is not clear enough, and the plate needs to be re-made. If the customer’s design is updated or changed, it also needs to be modified or re-made.

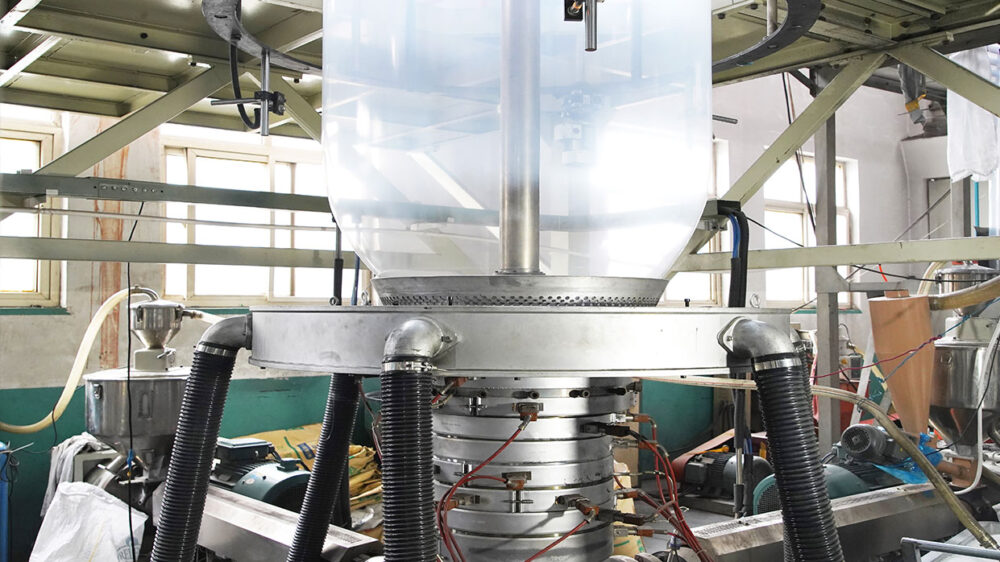

Film blowing

The film blowing refers to a plastic processing technology that heats and melts plastic particles and blows them into films. It is the first step in making plastic bags. Qingdao Xintongda Plastic Products Co., Ltd. uses fresh new plastic particles to blow out films, which are bright in color, clean and hygienic , The finished product stretches well and bears a large weight, so the plastic bag made of this film is of good quality and can be used for food packaging without worrying about its safety.

Plastic granules made of recycled waste plastics need to add color master batch to the plastic granules when blowing the film. The resulting film is prone to uneven coloring, brittle and easy to break, and the quality of the plastic bags made is poor, The price is low. This kind of film contains various impurities, so the plastic bag made of this kind of film is not hygienic and cannot be used as a food packaging bag. It is usually used as an industrial packaging bag or as a garbage bag. Here we want to remind consumers if you buy it for packaged food, you must carefully check the color and touch of the packaging bag, which can help you identify whether the food packaging is hygienic.

Printing:

Gravure printing is to print the whole roll of plastic film that has been blown. It is to print by the original plate/cylinder on the machine. The printing speed of this machine is very fast, which is very suitable for the production of plastic bags in large quantities. Now manufacturers of plastic bags basically use mechanical printing, and seldom use manual printing.

Qingdao Xintongda Plastic Products Co., Ltd. uses the most advanced 10-color automatic printing machine. The printing speed is up to 70m-150m/min. It can realize fast printing of large quantities of orders and shorten the delivery time.

Composite/Lamination

The basic principle of plastic composite flexible packaging: Each material has different advantages and disadvantages. It is a technology to bond two or more layers of materials together through a media (such as glue) to achieve better performance of packaging films and bags. This technology It is called “lamination process” in the production process.

Solidification

The purpose of solidifying is to speed up the curing of the glue between materials.

Usually the curing time is 48-72 hours, to ensure that the plastics of different materials are fully compounded into one. This is an important prerequisite for good printing.

Bag making

The printed film is ironed and cut into plastic bags by a bag making machine;

Qingdao Xintongda Plastic Products Co., Ltd. uses the most advanced bag making machine for ironing and cutting, to make the whole bag nice.

QA

During the printing and bag making process, the QA workers will test the check the printings carefully, the bags printing parts will be picked out.

And the QA workers will pick out all the bad making one out. To keep the left bags nice looking of good quality.

From the materials to the stock in, Xintongda Plastic Co.ltd have been doing every effort to keep the high quality and offer the best service.