With the increasing progress of the plastic packaging industry, printing effects have also made different degrees of progress.

1. Matte finish packaging

The matte finish packaging bag will be soft and the color is darker. This is to use a different plastic film MOPP when it is printed, and the design will be diretly printed on the matte film then the packaging will be matte.

2. Glossy finish packaging

The glossy bag is directly printed on the PET when it is printed, and the entire process does not need to be treated with any special treatment, and the bag made of this is more shiny and smooth.

3. UV packaging

The UV effect was first applied in the paper packaging industry, and then it also led to changes in the printing effect of the plastic packaging industry. The UV effect is simply to gather matte and glossy printing effects on a bag, showing part of the printing effect to be matte and other part of the packaging to be bright. Making matte in that place is based on the needs of customers, so that it can show the value of customized services.

Regarding the UV effect, only the process is that after the PET plastic membrane is printed, in the last step of printing, for a layer of matte oil on a specific local diagram, showing the printing effect of some matte part of the bright surface. It can be seen that matte oil is the importance of printing effect.

4. Golden Printing

Many customers are very interested in golden printing effects. This printing effect has high requirements for inks, so it only can be done by gravure printing. When the packaging is printed by gravure printing, we need to specialize in the golden ink and print it on the bag.

In order to make the golden effect look better, the effect of gold is usually made into shiny, which will make the design look more unique.

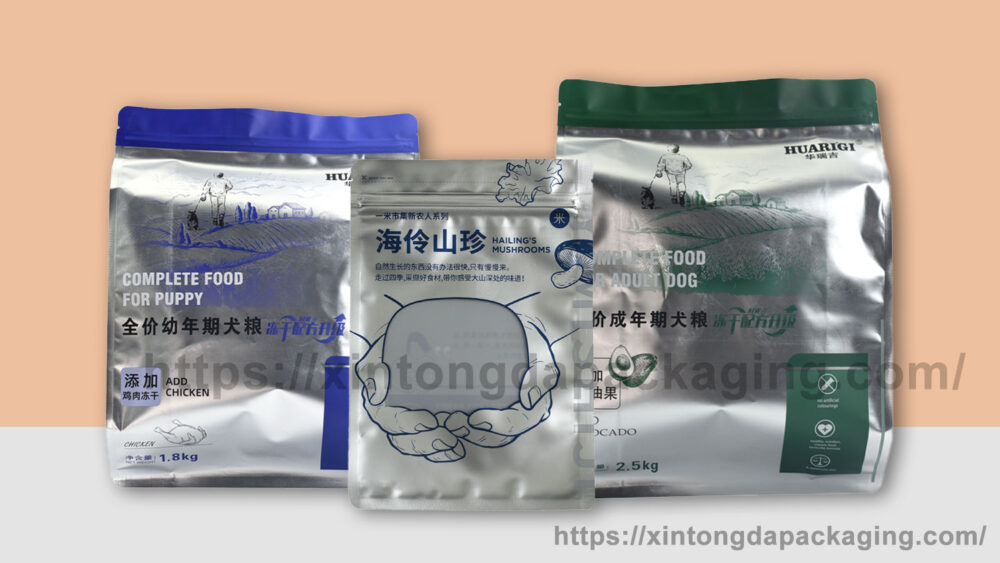

5. Aluminum Leakage

Aluminum leakage usually appears on the bags with aluminum foil. For common bags, in the last step of printing, we will add a layer of white ink, which will make our design more three -dimensional. For the part with aluminum leakage, it will not be printed with white ink, so that it can better retain the metal texture of aluminum foil. Just simply saying, the aluminum foil is leaked directly.

6.Holographic Printing

What is the holographic packaging?

Our holographic packaging will have different effects when viewed from different angles, which is its uniqueness.

So how to make a holographic packaging?

For holographic packaging, the most important thing is the holographic film.

We can make holographic bags with aluminum foil or without aluminum foil.

When making aluminum foil holographic bags, we need to apply high-purity related metal aluminum on the holographic film in a uniform pattern under the action of a high-temperature vacuum, so that the metal aluminum is in its own.It produces a strong decorative effect on the application body, and finally improves the barrier property of the material itself in the later application.

After the holographic film is finished, we can compound related materials in sequence according to the order of laminating. For example, the first layer is PET or MOPP with printing, the second layer is holographic film with aluminum, and the third layer is PE, in order to laminate.

When making holographic bags without aluminum foil, the process of spraying metal aluminum is omitted, and the printed film, holographic film and PE or other inner layer materials are directly laminated, and the bag is still holographic.Whether this bag is aluminized or not, we can make it fully holographic or partly holographic.

Fully holographic or Partly holographic.

So how does the full holographic come out? Whether the bag is fully holographic or partly holographic is closely related to printing. As we know, white is also a must-have color when we make plates. For holographic bags, white ink is dispensable. If we want to make a completely holographic bag, then we don’t need to brush a layer of white ink during printing, so that the holographic effect can be shown through the printing film.

If the bag is partly holographic, we must first determine which part is to be holographic and which part does not need to be holographic. Then when printing, white ink is not printed on the place that needs to be holographic, and white ink is printed on the place that does not need to be holographic, so that it is easy to have a different printing effect.

The above is the sharing about the printing effect of plastic packaging. If you want to get more information about plastic packaging, you can contact us as soon as possible. We can provide you with comfortable and all-round services.

For more information, please consult our company homepage.